Rewiring Global Value Chains

The global economy has entered a new era marked by disruptions arising from geopolitical challenges, resource competition, emerging technologies, and climate change. Moreover, manufacturers are also struggling with the added burdens of high inflation, labor shortages, and an ever-growing web of stringent regulations aimed at curbing waste and emissions. All put together, these challenges are straining the global value chain, unearthing existing vulnerabilities, and changing demand-supply equations.

As the risks of these disruptions grow in frequency and intensity, securing global value chains has emerged as a top priority in executive boardrooms, and are trickling down throughout organizations. Manufacturers are rethinking their operational strategies and redesigning their value chains with the objective of securing them from future potential shocks.

Many of the issues currently facing manufacturers date back decades, but the underlying fragility of the world’s complex supply chains were first truly unearthed as a result of the COVID-19 pandemic. Since then, successive geopolitical events such as the Russian invasion of Ukraine and conflicts in the Middle East have severely impacted the movement of goods, services, and people around the world, resulting in escalating commodity process.

These disruptions have contributed to a consensus among decision makers for the necessity of a robust and resilient supply chain. Today, the aperture of focus for supply chain decision makers has expanded beyond the cost paradigm to include the importance of reliability and resilience in the face of emerging uncertainties.

The threat of climate change on global value chains

While much has been written about the impacts of geopolitics and COVID-19 on global supply chains, there is another risk that is rapidly becoming a major, likely long-term source of potential disruption: climate change.

With greenhouse gas (GHG) and carbon emissions receding slowly, the adverse effects of climate change have mounted in recent years, resulting in erratic weather patterns and natural disasters, ranging from flash floods, prolonged drought or rainfall, and bush fires. To be sure, environmental disasters are not new to us, but with the accelerating impacts of climate change, these events aren’t just increasing in intensity but also frequency. According to the US’s National Centres for Environmental Information (NCEI), billion-dollar weather and climate events, where costs reach or exceed US$1 billion, are now occurring every three weeks. Just 40 years earlier, a disaster of a similar scale would only occur once every four months.

Greater frequencies of extreme weather events translate to more disruptions, extended delivery periods, lower output and – ultimately – much higher costs. By 2026, environmental risks on global supply chains are estimated to cost $120 billion in losses, with some projections suggesting that this could potentially rise to $25 trillion by 2050.

The last five years have proven to be a high watermark for climate risks, especially as economies across the world have become increasingly dependent on global supply chains to access a whole range of goods and services. A single disaster in one region can impact the flow of raw materials to other economies, creating a cascade of shocks and delays. In 2022, for example, Hurricane Lan struck the US and Caribbean, resulting in a 75% drop in shipments and delays lasting around 2.5 days. At times, these delays could have severe consequences, as Brazil experienced when a drought impacted an Amazon port resulting in low water levels that prevented the distribution of food and water to remote villages.

From all the threats posed by climate change to supply chains, rising sea levels are potentially the biggest. Coastal communities, transportation networks and infrastructure are likely to face the greatest risk, but so too will other sectors such as agriculture. For example, in the major rice-growing regions in Asia Pacific, such as the low-lying deltas of the Ganges, the Mekong, the Yangtze and elsewhere, tidal waves have impacted rice production by increasing water salinity while droughts are stressing farmers’ ability to plant crops. As these impacts ripple out across the region’s rice production capabilities, other neighboring economies that depend on access to this staple crop could face food security issues.

Ultimately, the burden of these delays is borne by the everyday customer, as manufacturers and companies pass on their inflated costs. Therefore, it is essential to evaluate the risks, make calculated decisions to lower exposure to climate risk and ensure uninterrupted global trade.

Developing sustainable global value chains

Minimizing the economic costs and developing resilient, sustainable supply chains will require a fusion of restructuring supply chains and emergent technologies. Monitoring of climate events will be essential to approaching disasters and planning to minimize damages, which will necessitate investment into cutting edge technologies.

Digital tools such as the Internet of Things can source information from the network of connected devices and sensors and help in preparedness by actively monitoring threats. Deploying artificial intelligence at the same time lays the groundwork for real-time monitoring and predictive capabilities, allowing companies to identify potential risks and mitigate them before they hit.

The availability and sharing of data are vital for monitoring and predicting extreme weather events. Climate risk data which is helpful for decision making is difficult to acquire from suppliers. Solutions providing companies the ability to monitor their portfolio, supply chain assets, identify risks, and share inputs to suppliers are essential in reducing disruptions and supporting sustainability commitments.

Taking cognizance of the climate threat and actively mitigating it will not only create secure supply chains but will also enable uninterrupted flow of essential, life-sustaining commodities across the globe.

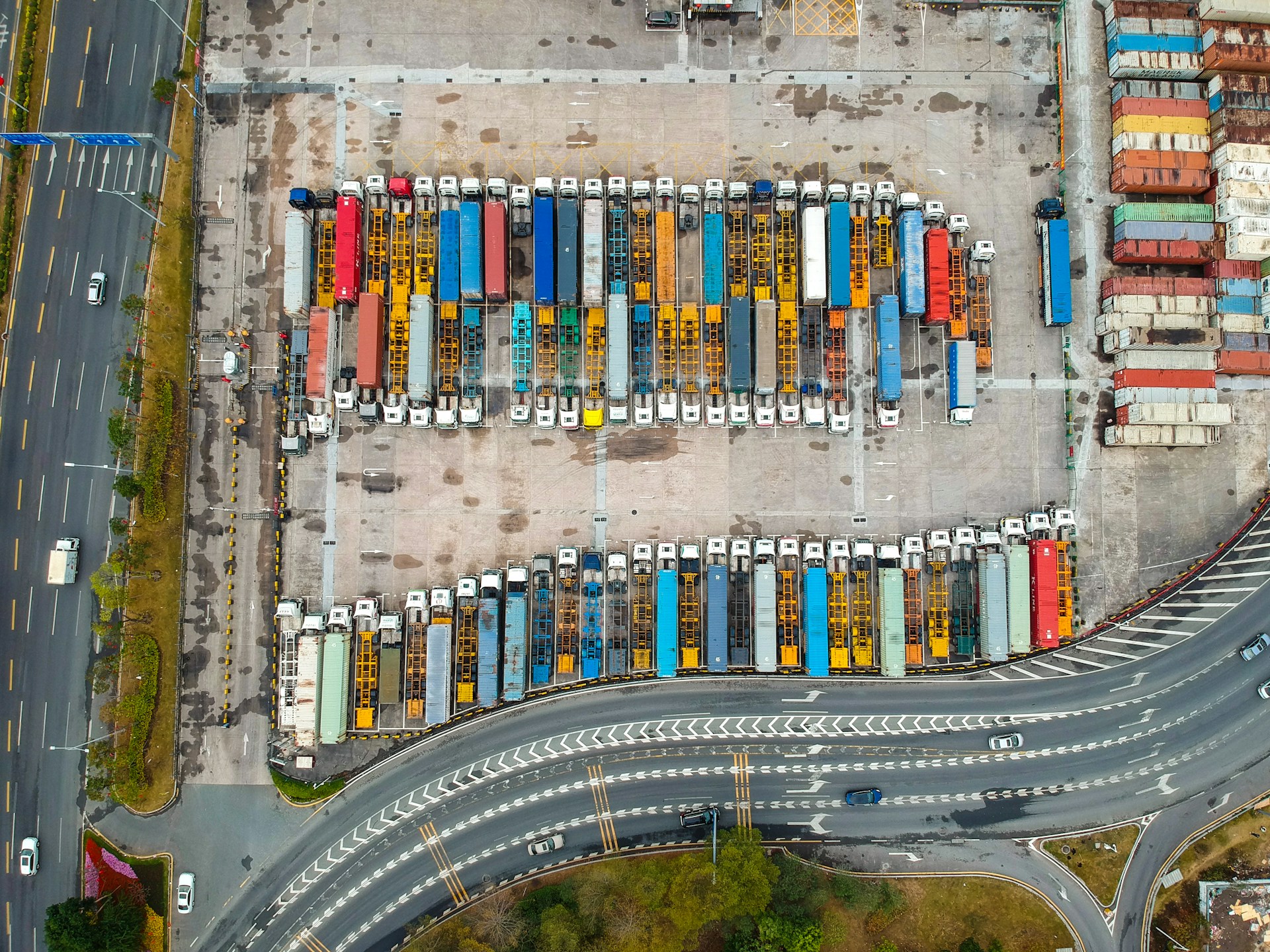

Photo Caption: Greater frequencies of extreme weather events translate to more disruptions.