Promoting the Effectiveness of Industry 4.0

The Fourth Industrial Revolution or Industry 4.0 (i4.0) is the interplay between advanced technologies and the manufacturing sector to realize enhanced productivity, flexibility, agility, and real-time decision making. The technologies powering i4.0 are Internet of Things (IoT), cloud computing, AI and machine learning, edge computing, and cybersecurity.

In 2023, the global i4.0 market size reached US$139.8 billion, and is expected to grow at a CAGR of 16% to reach US$547.1 billion by 2032, owing to increasing demand for smart manufacturing and automation.

GE, a global manufacturing behemoth, has already been reaping the benefits of automating its manufacturing processes. In its aerospace division, the company has introduced a generative AI platform that enables its 52,000 employees “to engage in interactive conversations with the AI, generating new ideas and solutions for the aerospace industry.”

IoT is another great i4.0 technology that is already in use in several factories around the world. Airbus is using IoT to scan aircrafts under production in the factory floor, determining bolts needed to install the airplane. This information is then transferred to a robotic tool, which completes the task. This has helped Airbus “streamline tens of thousands of steps in the assembly of an airplane, which can have as many as 400,000 bolts and screws alone and uses more than 1,100 different tools.”

As it evolves, i4.0 offers the promise of increased productivity, efficiency, and sustainability across various sectors. However, to fully harness the potential of i4.0, a robust infrastructure must be in place, and systems must be intelligently integrated and adaptable. In this context, several critical questions arise: Can highly integrated systems become self-regulating and easily reconstituted? How can interactive needs be elicited to ensure speedy implementation? Should human-centric demands take priority in this technological revolution?

The Need for a Vast Infrastructure

i4.0 depends on the seamless interplay of advanced technologies, which requires a vast and sophisticated infrastructure bandwidth. This infrastructure includes high-speed communication networks, cloud computing, data analytics platforms, cybersecurity frameworks, and a large array of IoT-enabled devices. Without the underlying physical and digital frameworks, the promise of i4.0 remains theoretical.

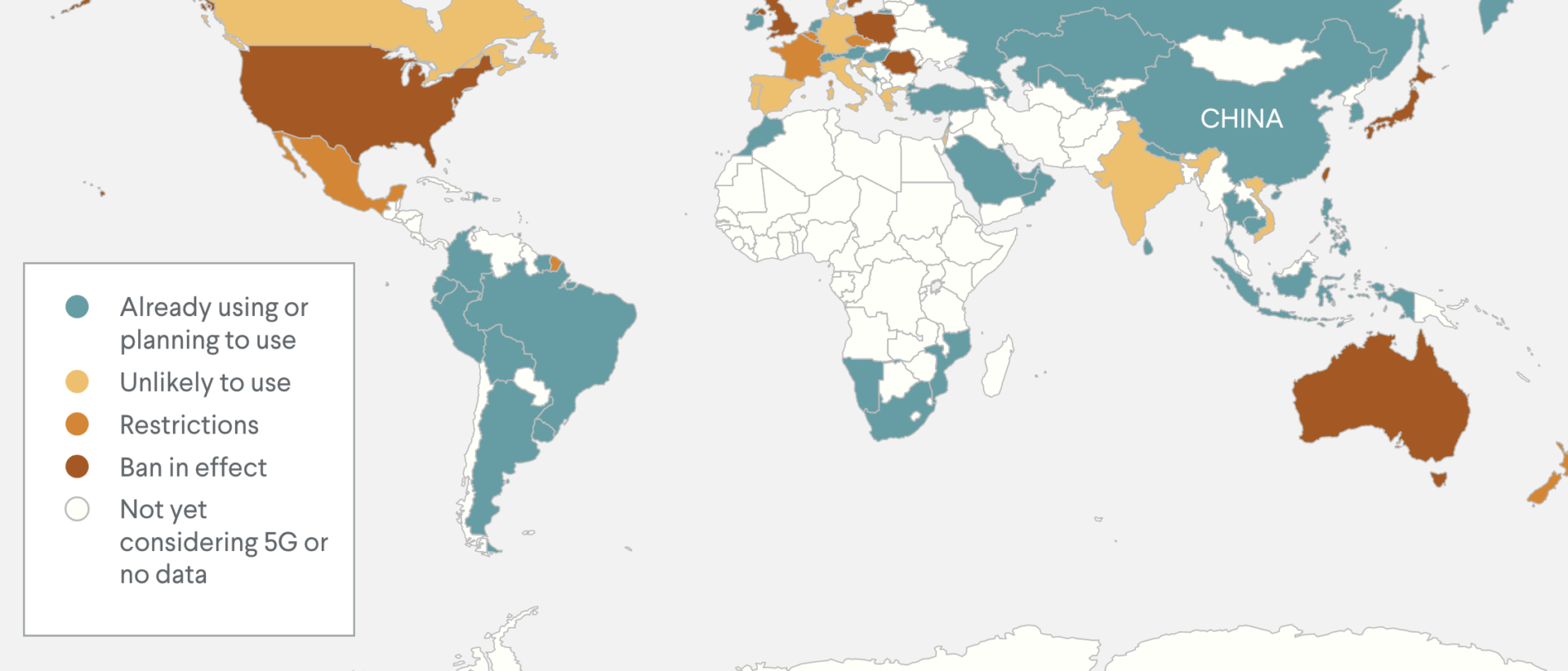

The advent of 5G will be a gamechanger in pushing both the development and intake of i4.0. More than ever before, 5G will make it absolutely possible to connect manufacturing plants wirelessly, transmitting data with extremely low latency and high reliability. 5G is up to 20 times faster than 4G, with peak data transfer rates of 20 Gbps.

With the introduction of 5G, factory floors will become more flexible, allowing workers to access mobile operating panels that can seamlessly connect to various systems and equipment. This will also support safety-critical functions, like kill switches. Currently, such devices are typically fixed to each machine. However, with 5G, fewer devices will be needed, leading to cost reductions. Additionally, working conditions for employees will improve, as they will be able to access machines more quickly and conveniently.

Can Highly Integrated Systems Become Self-regulating?

A key characteristic of i4.0 is the interconnection of systems that can communicate, collaborate, and make decisions with minimal human input. AI-driven automation enables machines and systems to collect data, learn from it, and optimize processes autonomously. This self-regulation is made possible through a combination of machine learning, predictive analytics, and intelligent algorithms that can adjust operations in real time.

Despite the potential for self-regulation, human oversight will still be necessary, particularly in ensuring ethical and safe deployment. Trust in autonomous systems will hinge on their ability to function safely without compromising on quality, security, or ethical standards.

Article 14 of EU’s AI Act, which is scheduled to enter into force in August 2026, requires AI developers to design high-risk AI systems “in such a way, including with appropriate human-machine interface tools, that they can be effectively overseen by natural persons during the period in which they are in use.”

Speedy implementation of i4.0 technologies depend on the ability to elicit and address interactive needs, making the technology intuitive and user-friendly. Prioritizing human-centric demands – especially those related to workforce transformation, ethical considerations and sustainability – will be crucial to ensuring that i4.0 benefits society as a whole, rather than just advancing technology for its own sake.

The journey to i4.0 is as much about understanding and meeting human needs as it is about technology, and the two must evolve in tandem for long-term success.

This topic will be discussed at the upcoming Horasis Global Meeting, being held in the city of Vitória, Brazil. The meeting will take place between 25-27 October 2024, bringing together leaders from governments, businesses, and civil organizations to help address global challenges such as inequality, peace, and climate change.

Photo Caption: View of a refrigerator manufacturing plant’s fully automated side panel forming line.